Paddy Selection

No compromises are made in the process of choosing the Paddy. Only the finest paddy is selected with good grain quality as this will determine the overall quality of rice that is produced. A high-yield potential and highly resistant paddy are selected to minimize loss.

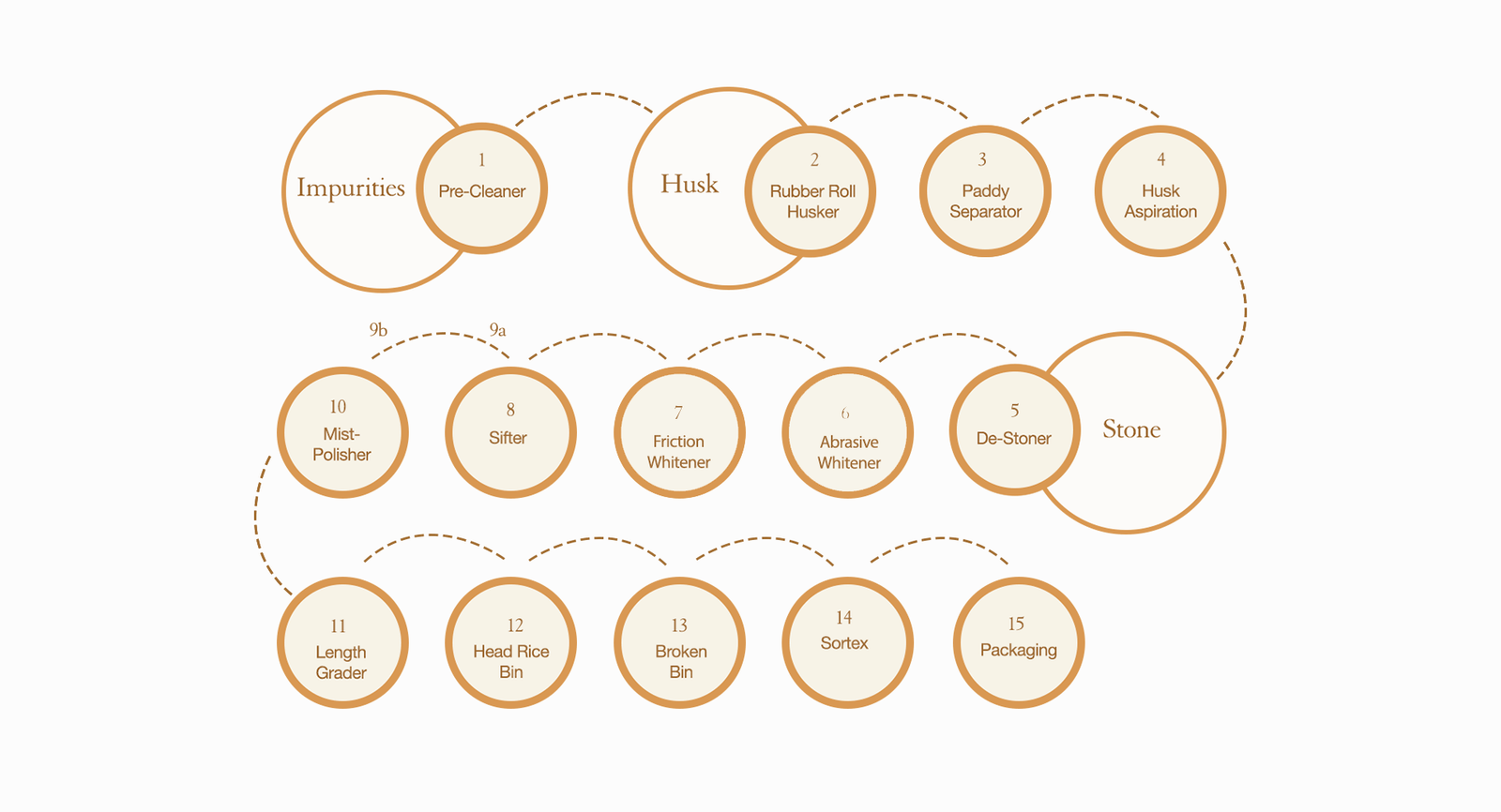

Paddy Cleaning

All contaminants, such as dirt, stones and more are taken out of the paddy when it arrives at the mill. Immature grains are also thrown away if discovered. Rice paddy is dried effectively using modern dryers that remove any moisture from the paddy.

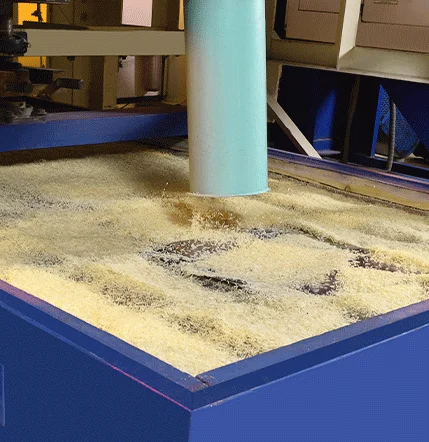

Milling and Warehousing

During the milling stage, the husk of the dried-out paddy is removed. The rice at this stage has a brown texture due to the bran layers on the rice. Modern moisture, temperature controlled, state-of-the-art storage systems are utilized to age the rice for at least 1 full year, helping the rice output a fuller taste and aroma.